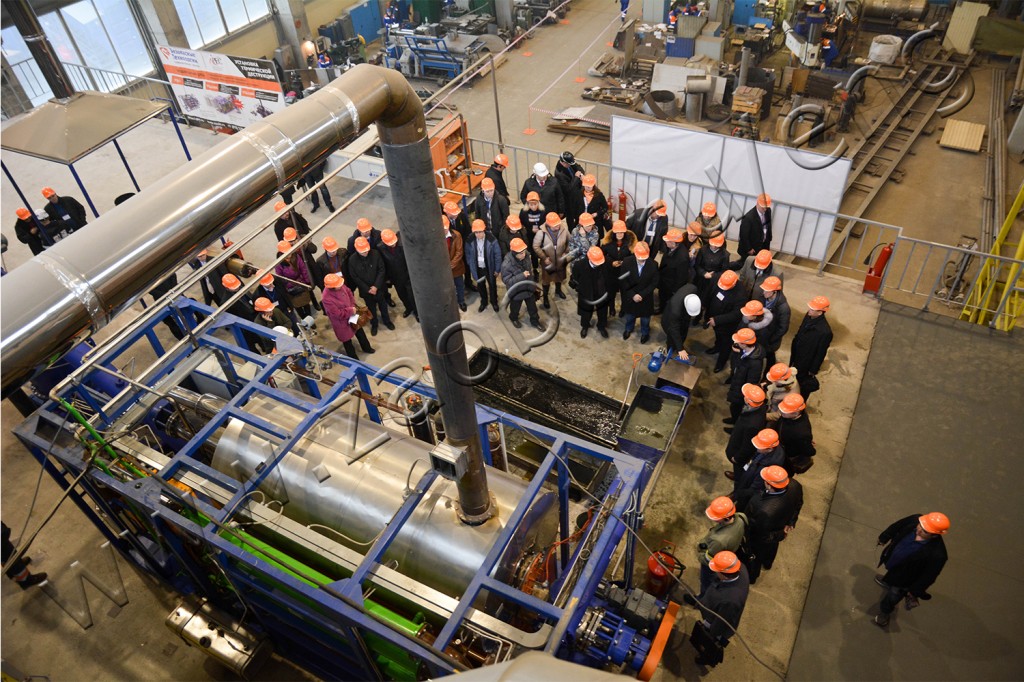

Technopark ST-Arsenal has been opened! Welcome to the demonstration testing of the equipment!

Based on the principle of ‘import substitution’ declared by the Russian government for the reason of economic sanctions imposed by the West, the importance of the domestic technologies and equipment increases drastically. This can be said as well about the environmental protection sphere. Every year a lot of industrial fairs are held in many Russian cities, including capital cities that are dedicated to the equipment and processes designed for safe and effective waste utilization. However it is not always convenient to get acquainted with the new equipment in the limits of the industrial exhibition. The technopark format offers more possibilities for learning the capabilities and characteristics of the equipment in its natural conditions, to say more, being described by engineer and not the sales man.

Based on the principle of ‘import substitution’ declared by the Russian government for the reason of economic sanctions imposed by the West, the importance of the domestic technologies and equipment increases drastically. This can be said as well about the environmental protection sphere. Every year a lot of industrial fairs are held in many Russian cities, including capital cities that are dedicated to the equipment and processes designed for safe and effective waste utilization. However it is not always convenient to get acquainted with the new equipment in the limits of the industrial exhibition. The technopark format offers more possibilities for learning the capabilities and characteristics of the equipment in its natural conditions, to say more, being described by engineer and not the sales man.

Safe Technologies Industrial group, the Russian company successfully engaged in designing and ‘turnkey’ construction of the environmental protection facilities and equipment, announces the opening of its own Technopark based on its industrial site ST-ARSENAL.

On its premises potential clients and partners have the possibility:

- to witness the equipment working cycle in real time and to inspect its assemblies in close range

- to consult the process designer or engineer

- to conduct his/her own test on the particular types of waste

- to take samples of the product with the purpose of further investigation in relation of its future use

Among the equipment exhibited at the Arsenal Technopark one finds the cutting edge serial equipment designed for waste utilization – UTD and KTO plants, made by Safe Technologies IG.

The thermal decomposition plants (UTD) involve the low temperature pyrolysis process (thermolysis). This kind of equipment is designed for utilization carbonhydrate- containing wastes and allows recovering useful components from old automotive tyres, rubber, oil sludge and oil production waste, plastic masses, foils, used lubricants, etc. Those components are: pyrolysis gas, fuel oil and dry residue.

The plant exists in two modifications, batch production and continuous production with the capacity 100 – 2000 kg/h. Energy recovery option is available for bigger plants with the production of hot water for local networks.

Thermal destruction plants (KTO) are based on incineration principle. Their capacity varies from 50 to 4000 kg/h. They are built around different types of furnace – hearth, rotary kiln and cyclone reactor for liquid and gaseous waste. The KTO equipment is designed for the wide range of waste types: MSW, medical and biological waste, industrial waste, sewerage sludge, etc. The outcome is the ash of 4th hazard class, non-hazardous according the Russian legislation. . Energy recovery option is provided for bigger plants with the production of hot water, steam or electricity.

Both UTD and KTO plants are highly automated. Automatic control system controls and monitors the process displaying all the main parameters on the control touchscreen. The contact between waste and personnel is either minimized or non-existent due to automatic loading assemblies.

The full set of documents and permits enabling the commissioning and operating the plant is available, together with State Expert body approvals.